TEL:+86 0536-6162866+86 187-6464-2379

ADD:No.19, Shunde Road, Zhucheng City, Shandong, China

WEB:www.clj20089.cn

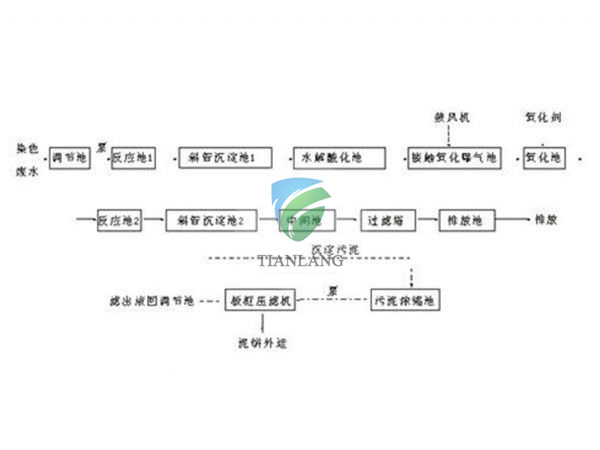

Dyeing sewage treatment plant

-

MS:Katherine Wong

+86 187-6464-2379

-

TEL:+86 0536 6162866

MAIL:sales@cntianlang.com

-

Name: Dyeing sewage treatment plant

details

Note: The following are just a few common treatment methods. The specific processing method needs to be customized for you in combination with your situation. If you need detailed plans and quotations, please call our company service hotline, we have a dedicated technical staff to give you free programs and quotations.

There are two major links in the wastewater treatment of textile mills. First, the textile mills have to deal with the impurities of the raw materials themselves. Secondly, some water treatment agents such as coagulants to be added during the processing. There are a lot of methods in the process, but from a macro-enterprise point of view, we have to compare the infrastructure footprint between several methods, the cost of implementing the water quality project, and whether the treatment effect conflicts with the environment. and many more.

Generally, these processes are used to treat printing and dyeing wastewater:

1. Adsorption method: The most widely used in the physical treatment method is the adsorption method, which is a method of mixing powder or granules of porous substances such as activated carbon and clay with waste water, or allowing waste water to pass through a filter bed composed of granules thereof. A method in which pollutants in the wastewater are adsorbed on the surface of the porous material or removed by filtration.

2. Coagulation method: There are mainly coagulation sedimentation method and coagulation air flotation method. Most of the coagulants used are mainly aluminum or iron salts, and the bridge adsorption properties of basic aluminum chloride (PAC). better. The main advantages of the coagulation method are simple process flow, convenient operation and management, low equipment investment, small floor space, high decolorization efficiency for hydrophobic dyes, and disadvantages: high operating cost, large amount of sludge and difficulty in dehydration. Aqueous dyes have poor handling.

3. Oxidation method: Ozone oxidation method can obtain good decolorization effect for most dyes, but it has poor decolorization effect on water-insoluble dyes such as vulcanization, reduction and coating. From the domestic and international operating experience and results, the method has good decolorization effect, but it consumes a lot of electricity, and it is difficult to promote and apply it on a large scale. The oxidation process has a high efficiency in decolorization of printing and dyeing wastewater, but equipment investment and power consumption have yet to be further reduced.

4. Electrolysis method: Electrolysis has a good treatment effect on the treatment of printing and dyeing wastewater containing acid dyes, and the decolorization rate is 50% to 70%, but the treatment effect on wastewater with deep color and high CODCr is poor.

5. Biological method: In the biological treatment of printing and dyeing wastewater in China, surface accelerated aeration and contact oxidation are the majority. In addition, blast aeration activated sludge method, jet aeration activated sludge method, biological turntable, etc. are also applied, and the biological fluidized bed is still in the experimental application stage. Since the biological removal rate of chromaticity is not high, it is generally about 50%, so when the effluent color requirement is high, it needs to be supplemented by physical or chemical treatment.

Our company's anaerobic reactor treatment of printing and dyeing sewage is better, and received favorable comments from customers.

Tel

Tel Home

Home Products

Products