TEL:+86 0536-6162866+86 187-6464-2379

ADD:No.19, Shunde Road, Zhucheng City, Shandong, China

WEB:www.clj20089.cn

Chain scraper system for collecting bottom sediment and floating substances

-

MS:Katherine Wong

+86 187-6464-2379

-

TEL:+86 0536 6162866

MAIL:sales@cntianlang.com

-

Scraper description

Chain scraper system is suitable for skimming, dross and scraping sand in rectangular tanks such as sedimentation tanks, grit tanks, grease traps and other rectangular tanks in refineries, water plants or sewage treatment plants. This equipment should be used with auxiliary settings such as oil collection pipes and sludge discharge valves to separate the oil slick residue on the water surface and the sediment at the bottom of the pool to complete the initial purification treatment.

The non-metallic chain scraper is equipped with two parallel closed traction chains. It is equipped with a number of scrapers, and under the traction of the driving device, the chain and scraper run along the guide wheels and guide rails set up and down the sedimentation tank to form a quadrilateral track. Using the scraper to circulate slowly up and down, the oil residue floating on the liquid surface can be scraped from the inlet end to the inlet end of the oil collection pipe and discharged, and the sediment settled at the bottom of the pool can be scraped from the inlet end to the sludge collection tank at the outlet end and discharged through the sludge discharge valve, so as to complete the purpose of the first mechanical purification of sewage.

Features of chain scraper:

1) The number of scraping plates is large, and the ability to scrape mud is strong; The scraper moves slowly, has little disturbance to sewage, and is conducive to sedimentation.

2) The scraper makes continuous linear motion in him, does not have to commutate back and forth, and therefore does not need a stroke switch. The drive unit is located on a platform at the top of the pool, which is easy to distribute and maintain.

3) No additional mechanism is required, and it can double as a skimmer at the same time.

4) There are no heavy structural components and supports in the system, and the energy consumption of the system is low.

Overall composition

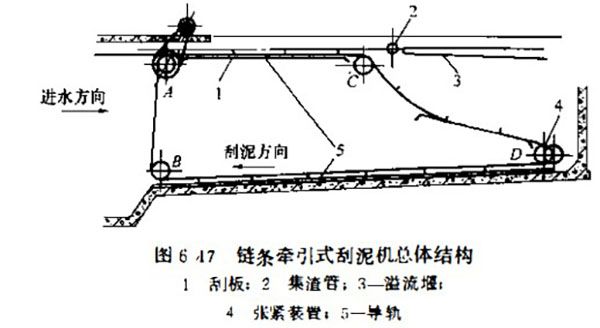

Figure 4-2-1 is the overall structure of the chain scraper, which is mainly composed of drive device, transmission chain and sprocket, traction chain and sprocket, scraper, guide wheel, tensioning device, sprocket shaft and guide rail. A safety pin is installed on the active sprocket of the drive sprocket for overload protection, as shown in Figure. 4-2-1.

Figure 4-2-1 Overall mechanism of chain plate scraper

V. Working principle

1. The chain scraper is to continuously remove the solid suspended solids floating on the water surface and the sludge at the bottom of the pool, move along the pool surface and the bottom of the pool, and push the suspended solids from the inlet end of the liquid level to the outlet end. It can be applied to rectangular primary and secondary sedimentation tank inner surface skimming and bottom scraping operations, as well as surface skimming of various tank shapes, and has been widely used in the water treatment industry in recent years.

2. Under the drive of the peripheral drive device, the main beam travels along the top of the pool at a linear speed of 2.0m/min with the central rotating support as the axis, and the lower part of the main beam is connected to the bracket, sludge scraper, etc. When the main beam rotates, the scum scraper skimming the liquid level from the center of the pool to the pool circumference, collected in the chain scraper area, the collected dross moves with the host around the pool to the skimming hopper, scrapes into the skimming hopper through the chain activity of the scraper plate, and is discharged to the outside of the pool.

3. When the scraper reciprocates, there is a layer of sludge at the bottom of the pool that is always moving forward until it falls into the mud collection trench. The reciprocating movement of the scraper also has the effect of thickening the sludge, which is important in practical applications. When the amount of sewage is equal, the higher the concentration of sludge, the lower its water consumption rate, which also reduces the loss of water and energy.

1. Main structure

(1) Drive mechanism

The drive mechanism adopts the helical gear reducer directly connected to the motor, which is provided by Shandong Tianlang Environmental Protection Technology Co.,Ltd. with high transmission efficiency and stable operation. The safety service factor of the reducer ≥ 12

(2) Drive chain

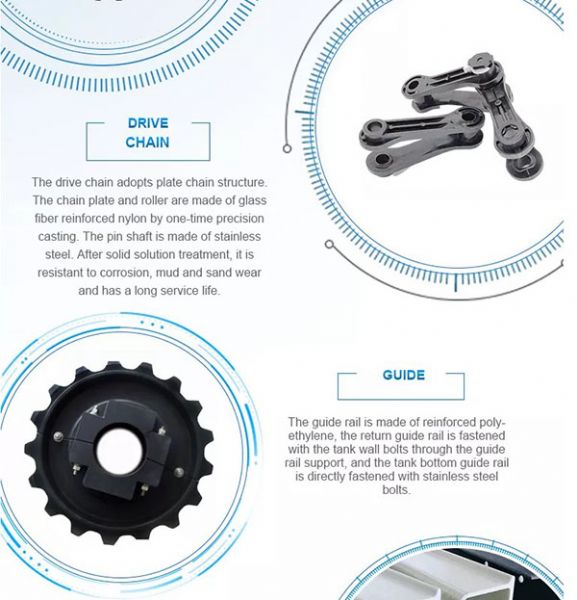

The drive chain is made of glass fiber reinforced nylon rollers, stainless steel chain plates, and pins. The pitch is 25.4mm, and the transmission movement is stable, accurate, and efficient. Considering the harsh working environment, the safety factor is 8.

(3) Scraper device

The underwater sprocket is made of glass fiber reinforced nylon precision casting, and the transmission movement is accurate and reliable. The chain pitch is 152.4mm, which is specially designed and manufactured. The drive chain adopts the plate chain structure form. The chain plate and roller are made of glass fiber reinforced nylon by one-time precision casting.

The scraper is made of high glass fiber + toluene dimethyl polyester (glass fiber reinforced plastic), which has strong rigidity and corrosion resistance. The installation distance of the scraper is 2.74 meters. The scraper is installed with a wear-resistant fiberglass-reinforced nylon, which is in contact with the upper and lower guide rails, and can be exchanged on both sides. long lasting. time wear. The guide rail is made of reinforced polyethylene, the seeding guide rail is fastened to the pool bolt by the guide rail bracket, and the bottom rail is fastened with stainless steel bolts.

(4) Scum collector

The tilting tube type scum collector has simple structure, no power device and reliable operation. The seal is made of binary B inner rubber, and the scum collector tube is made of stainless steel. The diameter of the pipe is 400mm, and the thickness of the pipe wall is 6mm. The scum collector discharges the collected scum into the scum well.

Manually operate the scum collector installation vehicle at the center of the slag-spreading side of each sedimentation tank, using handwheel operation, and the manual operating force is less than 150N.

(5) Electrical control

The electric control cabinet has the protection function of motor phase loss, undervoltage, leakage, etc. At the same time, it has the function of dynamic and automatic control. The PLC interface is reserved for joint control with other equipment, and the acceptance signal is sent to the central control room. The electric control cabinet is outdoor type, and the protection level is IP55.

2. Working principle

The scraper on the rotating chain is used to scrape the mud and sand deposited at the bottom of the pool into the sludge collection bucket, and the scum on the pool surface is collected into the scum collector, which can be operated continuously or intermittently.

3. Scope of supply

Supply of the whole machine, including auxiliary mud plate, drive device (motor, reducer, drive chain)

Guide rails and brackets, scraper chains, drive sprockets, all mounting accessories and fasteners

Electric control box and spare parts

Tel

Tel Home

Home Products

Products